Thursday 28th August 2025

Behind the excitement of exploring new destinations lies a hidden danger that most travellers never consider – carbon monoxide poisoning. This invisible, odourless gas has tragically claimed the lives of British travellers abroad, including 24-year-old Hudson Foley who passed away while backpacking in Ecuador.

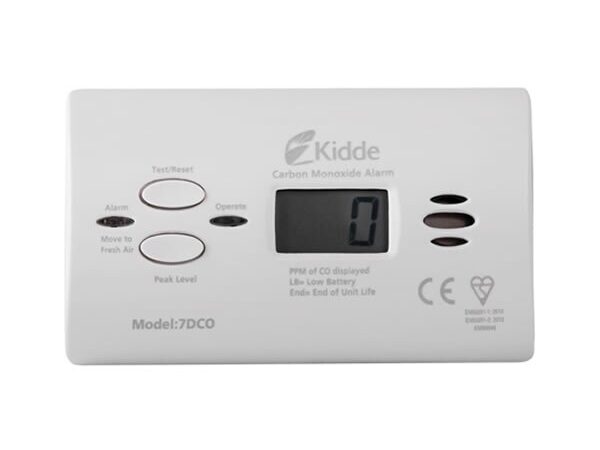

We’re proud to support the Pack Safe Appeal, a campaign launched by Hudson’s family to prevent further tragedies and encourage all travellers to pack a portable carbon monoxide detector. Through our partnership with the Safer Tourism Foundation, we’re offering 15% off our travel CO alarm with code HUDSON15 – because no family should endure such heartbreak.

What happened to Hudson Foley and why does his story matter?

Hudson Foley was living his dream. The 24-year-old from Surrey had saved for months to embark on a structured travel programme across Latin America in May 2023. He was volunteering on local projects, learning Spanish and exploring Ecuador when tragedy struck.

On 30 August 2023, Hudson passed away from carbon monoxide poisoning in homestay accommodation in Quito. He’d been feeling unwell for several days – experiencing sickness, lightheadedness and fainting spells. These symptoms were early warning signs of carbon monoxide poisoning.

Hudson’s blood contained 51.75% carbon monoxide – a lethal level when normal ranges sit between 0-5%. The invisible gas had been steadily poisoning him, and without a detector present there was no way to know the danger lurking in his accommodation.

Hudson’s mother, Cathy Foley launched the Pack Safe Appeal campaign to honour her son’s memory and prevent other families from experiencing such devastating loss. The campaign calls for travellers to pack portable CO alarms, and for the travel industry to prioritise carbon monoxide safety in accommodations.

Where can I buy a travel carbon monoxide detector?

You can purchase the UltraFire ULLCO10 directly from the Safelincs website, where we’re offering 15% off with code HUDSON15 in support of the Pack Safe Appeal. This brings the single unit price down from £21.77 to £18.50 (inc VAT), with further savings available on multiple units.

We’re also making travel safety more accessible by partnering with InMotion, the UK’s largest airport-based electronics retailer. You’ll find our travel CO detectors available at all InMotion stores across UK airports, retailing at £25. This means you can pick up this life-saving device even if you forgot to pack one before travelling.

InMotion stores, part of WH Smith PLC, specialise in airport-based technology retail, making them the perfect location to grab last-minute travel safety equipment. Whether you’re departing from Heathrow, Gatwick, Manchester or any other major UK airport, you can secure your carbon monoxide protection before boarding.

How common is carbon monoxide poisoning amongst travellers?

Carbon monoxide poisoning among British travellers abroad happens more frequently than most people realise. Hudson’s case represents part of a troubling pattern that spans decades, with young people particularly at risk due to their tendency to stay in budget accommodations with potentially inadequate safety standards.

The Safer Tourism Foundation, which supports the Pack Safe Appeal, was originally established following the carbon monoxide deaths of Bobby and Christi Shepherd nearly 20 years ago. That these tragedies continue to occur highlights how little progress has been made in protecting travellers from this preventable danger.

Many countries lack the strict safety regulations we take for granted in the UK. While carbon monoxide alarms are legally required in UK rental properties, this protection doesn’t extend to holiday accommodations abroad. Gas appliances may be poorly maintained, ventilation systems inadequate and safety checks infrequent or non-existent.

What makes carbon monoxide so dangerous for travellers?

Carbon monoxide poses a unique threat because it’s completely undetectable by human senses. You can’t see, smell, taste or hear this toxic gas – making it impossible to know when you’re being poisoned without proper detection equipment.

The gas is produced when fuel-burning appliances don’t operate correctly. Common sources in travel accommodations include boilers, water heaters, cookers, generators and heating systems. Poor ventilation or blocked flues can cause CO to build up to dangerous levels within enclosed spaces.

Early symptoms mirror common travel ailments – headaches, dizziness, nausea and fatigue. Many travellers dismiss these warning signs as jet lag, food poisoning, a hangover or adjustment to new climates. By the time symptoms become severe, it may be too late.

Carbon monoxide works by binding to haemoglobin in your blood more readily than oxygen, effectively suffocating you from within. High concentrations can cause unconsciousness and death within minutes, making rapid detection and evacuation crucial for survival.

Which portable carbon monoxide detector should I pack for travel?

Our UltraFire ULLCO10 Travel Carbon Monoxide Detector with Strap was designed specifically with travellers in mind. This compact, lightweight alarm offers comprehensive protection whether you’re staying in hostels, Airbnbs, caravans, boats or camping.

The detector is Kitemarked to both BS EN 50291-1 (for homes and static caravans) and BS EN 50291-2 (for caravans, motorhomes, camping, boats and general travel), giving you confidence in its reliability across different accommodation types.

Key features that make this ideal for travel include:

Portability and convenience

- Compact, lightweight design fits easily in any backpack

- Includes travel strap for clipping to bags or hanging in tents

- Can be wall-mounted or used free-standing

- 10-year sealed lithium battery eliminates the need for replacements

Comprehensive protection

- Clear, loud 85dB alarm audible throughout typical accommodation

- Visual LED indicators for power (green), alarm (red) and fault (amber)

- Separate test and silence buttons for easy maintenance

- End-of-life audible warning at 10 years

Quality and reliability

- BSI Kitemark approval ensures British safety standards

- 10-year product life with matching warranty

- Tested and certified for multiple environments

The complete package includes the detector, sealed battery, travel strap, wall mounting kit and comprehensive instruction manual.

How should I use my travel carbon monoxide detector?

Using your travel CO detector effectively requires some basic planning and awareness. As soon as you arrive at any accommodation, set up your detector in the sleeping area, ideally at head height when lying down. The travel strap allows you to hang it from bedposts, tent guy-ropes or cabin hooks.

Test your detector when you first set it up and familiarise yourself with the different LED indicators. Green means normal operation, red indicates a CO alarm, and amber signals a fault. The separate test button lets you verify the alarm is working, something you should do each time you move to new accommodation.

If your detector sounds, follow the GAS protocol immediately:

- Go outside into fresh air

- Ask for medical help and mention suspected CO poisoning

- Service – report the issue to accommodation providers

Don’t ignore symptoms like headaches, dizziness or nausea while travelling. These could indicate CO exposure, particularly if multiple people in your group experience similar symptoms simultaneously.

Remember to keep your detector with you throughout your journey. Different accommodations may have varying risk levels, and you never know when that small device could save your life.

What impact has the Pack Safe Appeal achieved so far?

The Pack Safe Appeal has gained significant traction since its launch, with support from various organisations committed to travel safety. Chelsea Football Club honoured Hudson’s memory at a home match, reflecting his lifelong support for the team. The Latin American Travel Association has incorporated CO safety messaging into their regional safety schemes.

Parliamentary support came from Barry Sheerman, former MP and Chair of the All-Party Parliamentary Carbon Monoxide Group, who highlighted the ongoing need for better awareness of CO risks abroad. Hudson’s family appeared on BBC Breakfast to share their story and promote portable CO alarm awareness to a national audience.

The campaign has successfully raised awareness among travel companies, online guides and government bodies about the need to communicate carbon monoxide risks more effectively. Travel providers are beginning to include CO alarms in recommended kit lists and provide safety briefings to customers.

Most importantly, the campaign encourages individual travellers to take personal responsibility for their safety by packing portable CO detectors. Every traveller who packs an alarm potentially saves not just their own life but also those of their travel companions.

The campaign saved the life of Emily Key and her travel companions when it alerted them to a carbon monoxide leak in their accommodation.

“I managed to persuade my rather reluctant daughter to take a CO alarm with her, on her recent trip to South America. I am so glad I did because only a couple of weeks later my daughter phoned me from a Bariloche hostel (Chile) to explain that the alarm had woken her up with its insistent beeping. She woke her friends and got them all to safety. I can’t thank Cathy (Pack Safe Appeal) enough for highlighting this potentially fatal situation and that having bought an alarm I saved my daughter and her backpacker friends’ lives. Emily is now in Brazil having fun in Rio! I’m not sure that she’ll want to come home.”

Louise Key (Emily’s Mum)

Transform your travel safety with one simple addition

Hudson Foley’s tragic passing reminds us that adventure doesn’t have to mean accepting unnecessary risks.

Our portable carbon monoxide detector could be the most important item you pack. We’re committed to supporting the Pack Safe Appeal through our HUDSON15 discount code, which is valid only on our website throughout the campaign. Every purchase helps raise awareness of travel carbon monoxide safety and honours Hudson’s memory by potentially preventing similar tragedies.