-

Contact

Sales & Customer Service

0800 612 6537 support@safelincs.co.uk Live ChatDelivery Enquiries

0800 077 6149 - Resources

Fire & Safety Solutions

CALL OUR TEAM NOW 0800 612 6537

Also FREE from UK mobiles

Free Delivery

on 100s of Products

Live Chat - Online

Instant help & Advice

Trade Discounts

and exclusive pricing

0% Credit Available

Open an account now

5 Star Customer Feedback

How Fire Extinguishers should be serviced

Fire extinguishers in businesses and organisations should be regularly serviced to ensure they remain in good working order and function correctly should they be needed.

It is the responsibility of a business owner or responsible person for a building to ensure that metal extinguishers are serviced by a trained and competent person (BFC, BAFE qualified etc) in accordance to BS 5306-3. This does, of course, not apply to service-free P50 fire extinguishers. Service-free extinguishers are visually inspected by the owner or their staff in line with the manufacturer's instructions.

Stored Pressure Metal Fire Extinguishers

Stored pressure fire extinguishers contain the extinguisher agent (water, powder, foam, CO2, etc.) and the pressurising gas (dry air or oxygen-free nitrogen) in the same cylinder.

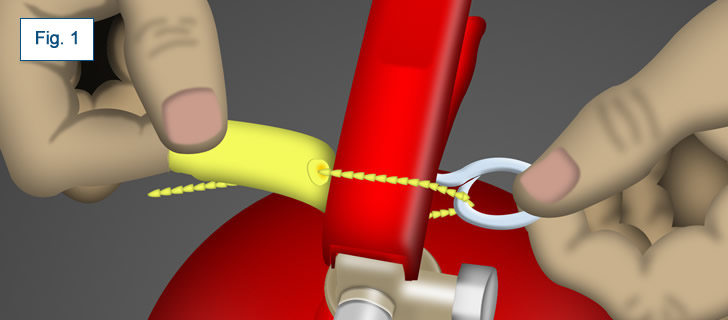

- Before moving the extinguisher, check that the safety pin/clip and tamper seal are in place (Fig. 1) and that the extinguisher has not been operated (if this is not the case, then make the fire extinguisher safe before going any further by fitting a safety pin and tamper seal)

- Check the extinguisher service label, if the extended service is not due then proceed.

- Visually inspect the fire extinguisher body for external corrosion or damage that could impair the safe operation of the extinguisher, in particular check the head cap. If this is made from plastic, check for UV degradation.

- Ensure that the manufacturer's extinguisher labelling is in good condition, legible and printed in English.

- Weigh the extinguisher ensuring that it meets the weight recorded on the service label (Investigation and recharge is required if a weight loss exceeds 10%).

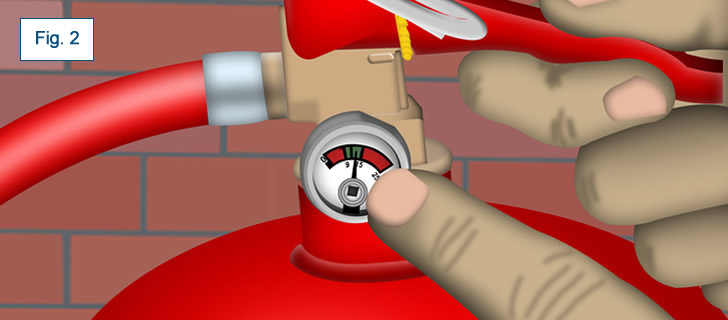

- Verify the pressure gauge indicator is in the green zone of the gauge (Fig. 2). Verify that the gauge is in working order by carrying out a gauge test with a pump gauge tester or pin test. (This step is not applicable for CO2 fire extinguishers)

- Remove the discharge hose from the extinguisher head cap, check the hose and nozzle for damage and ensure that the hose is clear from obstruction (Fig. 3). Remove the hose 'O' ring and replace if applicable.

- Break the tamper seal by withdrawing the safety pin/clip. In the case of a metal pin; check that it is in good condition. Refit/replace the safety pin/clip and then secure in place with a tamper seal.

- Replace any 'O' rings where components have been disassembled.

- Wipe down the extinguisher exterior with a cloth.

- Fill in the details required on the service label (date, weight, engineer initials and next service date).

- If applicable, ensure that the wall mountings are secure before mounting the extinguisher back in position

- If there is a sign above the extinguisher check that it is appropriate and is in good condition

Cartridge Operated Metal Extinguishers

Cartridge operated extinguishers contain the extinguisher agent (water, foam, powder, CO2 etc.) in the main cylinder (this is not pressurised) and a seperate gas cartridge containing highly pressurised CO2. Once the handle is squeezed the CO2 cartridge is pierced releasing the pressure into the main cylinder.

- Before moving the extinguisher, check that the safety pin/clip and tamper seal are in place and that the extinguisher has not been operated (if this is not the case, then make the fire extinguisher safe before going any further by fitting a safety pin and tamper seal).

- Check the extinguisher service label, if the extended service is not due then proceed.

- Visually inspect the fire extinguisher body for external corrosion or damage that could impair the safe operation of the extinguisher, in particular check the head cap. If this is made from plastic, check for UV degradation.

- Ensure that the manufacturer's extinguisher labelling is in good condition, legible and printed in English.

- Weigh the extinguisher ensuring that it meets the weight recorded on the service label (Investigation and recharge is required if a weight loss exceeds 10%).

- Unscrew the head cap assembly to not more than one third of extent necessary for full disengagement – this allows any pressure remaining in the extinguisher to escape through the automatic means of venting. Then continue to open the extinguisher slowly.

- Remove the extinguisher head cap away from the extinguisher body.

- Examine the head cap and operating mechanism for damage.

- Examine the gas cartridge and if safe to do so, remove the cartridge from the head cap. Visually inspect the gas cartridge for corrosion or damage – in either case replace the cartridge in accordance with manufacturer's instructions.

- Check if the gas cartridge is more than 10 years old – otherwise replace it.

- Check weigh the mass of the gas cartridge against that marked on the gas cartridge body.

- Remove the safety pin/clip and tamper seal from the head cap. Check for free movement of the safety pin/clip and replace if necessary. Check that the operating lever freely operates and is not damaged.

- Check that the firing pin is in place and operates correctly.

- Check that the discharge hose, hose nozzle, dip tube and strainer are free from obstructions and damage. Pass air through the discharge hose, dip tube and strainer, checking for blockages and correct operation.

- Examine the pressure release slots in the head cap threads – clean as necessary.

- Fit a new head cap 'O' ring.

- Fit a new discharge hose 'O' ring.

- Assemble the head cap, discharge hose, dip tube and gas cartridge together and put to one side so that the extinguisher body and contents can be dealt with.

- Empty the contents of the extinguisher into a clean container. Inspect the extinguisher medium to make sure that it is fit for re-use. If the medium is not fit for re-use then dispose of accordingly. All medium should be kept clean and free from debris at all times. Powder medium should be kept clean and dry and away from moisture.

- Examine the extinguisher body internally using a torch to check for corrosion and damage to the internal lining (powder extinguishers do not have lining).

- Return the original medium or fresh medium to the extinguisher – always adhere to manufacturer's specifications.

- Refit the head cap and tighten down firmly.

- Weigh the extinguisher total mass.

- Wipe down the extinguisher exterior with a cloth.

- Fill in the details required on the service label (date, weight, engineer initials and next service date).

- If applicable, ensure that the wall mountings are secure before mounting the extinguisher back in position.

- If there is a sign above the extinguisher check that it is appropriate and is in good condition.

Reviewed: 03/11/2020 (doc:23 V1.1). Our articles are reviewed regularly. However, any changes made to standards or legislation following the review date will not have been considered. Please note that we provide abridged, easy-to-understand guidance. To make detailed decisions about your fire safety provisions, you might require further advice or need to consult the full standards and legislation.