-

Contact

Sales & Customer Service

0800 612 6537 support@safelincs.co.uk Live ChatDelivery Enquiries

0800 077 6149 - Resources

Fire & Safety Solutions

CALL OUR TEAM NOW 0800 612 6537

Lines open today 8am - 6pm

Free Delivery

on 100s of Products

Live Chat - Online

Instant help & Advice

Trade Discounts

and exclusive pricing

0% Credit Available

Open an account now

5 Star Customer Feedback

Detector Testing Equipment

Fire alarm testing isn't just about compliance – it's about protecting lives and property. When detectors fail, people pay the price. That's why we stock professional-grade testing equipment, giving you confidence in your fire safety systems. What makes fire alarm testing equipment essential? Regular testing ensures your fire alarms are operational when they matter most. Smoke detectors, heat sensors, and carbon monoxide alarms should be checked at least once a year. But here's the thing – you can't test them properly without the right tools. Our detector testing equipment range covers everything from basic aerosol testers to advanced electronic calibration units. Whether you're managing a small office or a large commercial building, we've the tools that make testing straightforward and reliable. How do you professionally test smoke detectors? Professional smoke detector testing requires more than just pressing the test button. You need to create controlled conditions that mimic real fire situations. Aerosol smoke testers release a measured amount of artificial smoke directly into the detector chamber. This triggers the alarm in the same way real smoke would. Heat detector testing works differently. These devices respond to temperature changes, not smoke. Testing equipment for heat detectors uses focused heat sources or heated air to raise the temperature around the sensor. The detector should activate within its specified temperature range. Carbon monoxide testing needs specialised gas testers that release controlled amounts of CO gas. These testers ensure your CO detectors respond correctly to dangerous gas levels before they become life-threatening. Which testing equipment do fire safety professionals recommend? Professional fire safety engineers rely on equipment that delivers consistent, measurable results. Electronic testers with digital displays give precise readings and eliminate guesswork. Many professionals prefer combination units that can test multiple detector types with one device. Aerosol testers remain popular because they're simple to use and highly effective. Look for testers that produce the correct particle size to trigger modern photoelectric detectors. Some models feature extension poles for safely reaching high-mounted detectors. For larger installations, consider programmable testers that can simulate different fire scenarios. These advanced units help you understand how your detectors perform under various conditions. What safety considerations matter during detector testing? Testing fire alarms requires careful planning. You don't want to cause unnecessary evacuations or panic. Most testing equipment includes features that help you work safely and efficiently. Many aerosol testers now come with precision applicators that direct smoke exactly where you need it. This reduces waste and prevents accidental triggering of nearby detectors. Some units include safety caps that prevent accidental discharge. Electronic testers often feature countdown timers and automatic shut-off functions. These prevent over-testing, which can damage sensitive detector components. Look for units with clear visual indicators that show when testing is complete. How often should you test different types of detectors? British Standards recommend six-monthly inspections, including professional sensor testing, for most commercial fire detection systems. However, detectors in dusty or harsh environments may need more frequent testing. Heat detectors typically need less frequent testing than smoke detectors because they have fewer moving parts. But they still require annual verification to ensure they activate at the correct temperature. Carbon monoxide detectors need regular testing because they can lose sensitivity over time. Many professionals recommend testing commercial CO detectors every six months, especially in areas with gas appliances or vehicle access. What features should you look for in testing equipment? Portability is crucial when testing detectors across multiple locations. Look for lightweight units with carrying cases or belt clips. Battery life is vital – you don't want your tester dying halfway through a large installation. Accuracy and repeatability separate professional equipment from basic testers. Digital displays with precise readings help you accurately document test results. Some units can store test data or connect to smartphones for record-keeping. Safety features, such as automatic shutoff and precision controls, prevent accidents and equipment damage. Many professionals prefer units with interchangeable heads or attachments for different detector types. Why choose professional-grade testing equipment? Professional testing equipment pays for itself through reliability and efficiency. Cheap testers often yield inconsistent results or fail when you need them most. Quality equipment produces repeatable results you can trust. Professional units typically include calibration certificates and traceable standards. This documentation proves your testing meets regulatory requirements. Many insurance companies require this level of documentation for commercial properties. Advanced features, such as data logging and connectivity, help you maintain accurate and proper testing records. These features become essential for larger installations where manual record-keeping becomes impractical. Browse our complete range of professional detector testing equipment and find the tools that match your specific needs. Every device we stock meets British Standards and comes with full technical support to keep your fire safety systems working perfectly. Don't forget to maintain proper fire safety log books for your testing activities, and read our comprehensive guide on fire alarm testing and maintenance. Frequently Asked Questions (FAQs) Can I test detectors from ground level without ladders? Yes, all our detector testing equipment is designed for use at ground level. Our products include extension poles and spray applicators that safely reach high-mounted detectors, eliminating the need for ladders or scaffolding. What's the difference between weekly testing and professional testing? Weekly testing using the test button only checks the alarm's circuitry and sounder. Professional testing with specialist equipment triggers the detector's sensing mechanism in response to smoke, heat, or gas to verify that it responds correctly to real fire conditions. Do I need different testers for smoke and heat detectors? Many of our testing kits are compatible with multiple detector types; however, smoke and heat detectors require distinct testing methods. Smoke detectors need aerosol testers, whilst heat detectors require focused heat sources. We stock combination units that handle both types of products. How often do commercial fire alarm systems legally need testing? Commercial fire alarm systems require six-monthly inspections by trained engineers using specialist equipment. Additionally, business owners should test their systems weekly by activating manual call points to ensure the whole system sounds correct. Are your testing products suitable for both domestic and professional use? Our range covers both domestic and professional needs. We stock simple hand-held testers for home use right through to premium semi-automated kits for professional fire safety engineers. All products are compatible with leading manufacturers, such as SOLO and Testifire.

Read more about detector testing equipment...

Smoke Sabre Aerosol Smoke Detector Tester - 150ml

- Professional hand-held product for testing ionisation and optical smoke detectors

- Ozone and environment friendly

- Quick and safe

- 150ml size can

Solo A10 & A10S - Smoke Detector Test Aerosols

- Designed for use with the Solo 330 and 332 dispensers

- Delivers simulated smoke particles to the detector

- Supplied in 150ml or 250ml canisters

- Non-flammable and non-toxic

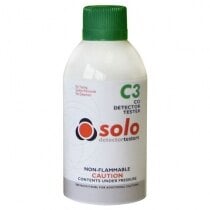

Solo C3 - Carbon Monoxide Detector Tester

- Designed for use with the Solo 330 dispenser

- Introduces CO to the sensor of the detector

- CO concentration level below the toxic threshold

- Non-flammable and safe to use

Solo C6 - Hand-held Carbon Monoxide Detector Tester

- Hand-held aerosol for testing domestic CO detectors

- Supplied with dispensing straw

- Contents: approx. 4 litres

- Introduces CO to the detector sensor

Solo 365 Universal Charging Kit

- Designed for use with the Solo 365 Battery Pack

- Works with most USB power sources and a wide range of international power supplies

- No large "power brick" required, reducing bulk and weight for transportation

Solo 425 - Heat Detector Tester 5m Extension Cable

- Designed for use with Solo Mains Powered Heat Detector Testers

- Allows heat detector testers to be used at height

- Length of cable: 5m/16ft

Solo 365 ES3 Smoke Detector Tester Cartridge (Pack of 3)

- Non-flammable chemical smoke

- Non-pressurised cartridge for ease of storage

- Comparable test capacity to Solo A3 and A10s aerosols

- For use with Solo 365 only

Solo 365 Replacement Cup and Membrane

- Contains simulated smoke to prevent wastage

- See-through plastic for checking indicator LEDs on detectors

- Quick and easy to swap out while on the job

- Works with the Solo 365's integrated proximity sensor

Solo 101 - Extension Access Pole

- For use with Solo or Testifire detector testing equipment

- 1.13m long extension pole

- Can be used on its own or combined with a telescopic access pole

- Multiple extension poles can be combined to achieve a working height of up to 9m

Solo 365 Adaptor for ASD Systems

- No-fuss functional testing of aspirating smoke detection systems

- Quick and easy to fit while on the job

- Small and lightweight – can be kept on hand at all times

- Works with the Solo 365's delayed start and manual purge options

Solo 365 Spare Battery Pack

- Rechargeable Lithium Ion battery pack

- Available as single units or pack of 4

- MicroUSB charging port

- Compact design for ease of use

Solo 770 - Cordless Heat Detector Tester Replacement 3.0Ah Battery Baton

- Designed to power the Solo Cordless Heat Detector Tester

- Also compatible with the Testifre system

- Provides power to the detector tester

- Rechargeable via the smart fast battery charger

Solo 727 - Fast Battery Charger

- Used for recharging Solo 760 and Solo 770 battery batons used with Solo and Testifire systems

- Provides a rapid charging time of 90 minutes

- Supplied with 12V and mains connections

- Ensures the cordless heat detector tester remains powered

Testifire Replacement Smoke Capsules 3 or 6 Pack

- Replacement smoke generating capsule for Testifire systems

- Non-pressurised canister - smoke generated on demand

- Available in packs of 3 or 6 capsules

- Colour coded blue for easy identification

Solo 610 - Protective Storage Bag

- Provides effective protection when transporting Solo or Testifire detector testing equipment

- Ideal for storing and carrying tester head units, battery batons, chargers and aerosols/capsules

- Includes a separate bag for access poles

- Allows technicians to store equipment in a tidy and compact manner

Testifire Replacement Carbon Monoxide Capsules 3 or 6 Pack

- Replacement carbon monoxide (CO) generating capsules for Testifire systems

- Non-pressurised canister - CO generated on demand

- Available in packs of 3 or 6 capsules

- Colour coded green for easy identification

Solo 100 & 108 - Telescopic Access Poles

- For use with Solo or Testifire sytems

- Lightweight and easy to extend

- Available in two lengths

- Non-conductive glass fibre construction

Solo 330 - Smoke Dispenser

- Used to introduce a simulated smoke to a detector

- Suitable for detectors up to 100mm/4" in diameter

- Used with the Solo telescopic access poles for safe testing at heights

- Allows 360 degree view of detector LED

Solo 365 Replacement Smoke Generator

- Designed for use only with Solo 365 equipment

- Automatically creates smoke when the Solo 365 cup is over a detector head

- On-demand, 5-second smoke cycles prevent wastage and detector contamination

- Easy to install, field-replaceable design – no manufacturer service required

Solo 200 - Universal Detector Removal Tool

- For use with Solo or Testifire systems

- Single, universal tool for detector removal, inspection and replacement

- Adjustable to suit the majority of smoke, CO and heat detectors

- Tool remains parallel with the ceiling

Page 1 (20 of 44 Products)

What is the legal requirement for fire alarm testing?

For fire alarm systems, there is a legal requirement for a six-monthly inspection to be conducted each year. This should be performed by a trained fire alarm engineer as they test all the smoke and heat detectors with specialist equipment without the additional risk of climbing. For more information on fire alarm system testing and servicing, please visit our services page.

How do you test a smoke detector and how often?

Domestic Users

Testing your smoke alarm is as simple as pressing a button. This is recommended to be done once a week. By pressing the test button, it tests the circuitry and sounder of the alarm.

Business Owners

Testing of the fire alarm system should also be done once a week. To test this kind of system, one of the manual call points should be activated to ensure that the system is working correctly and it effectively sounding the whole system.